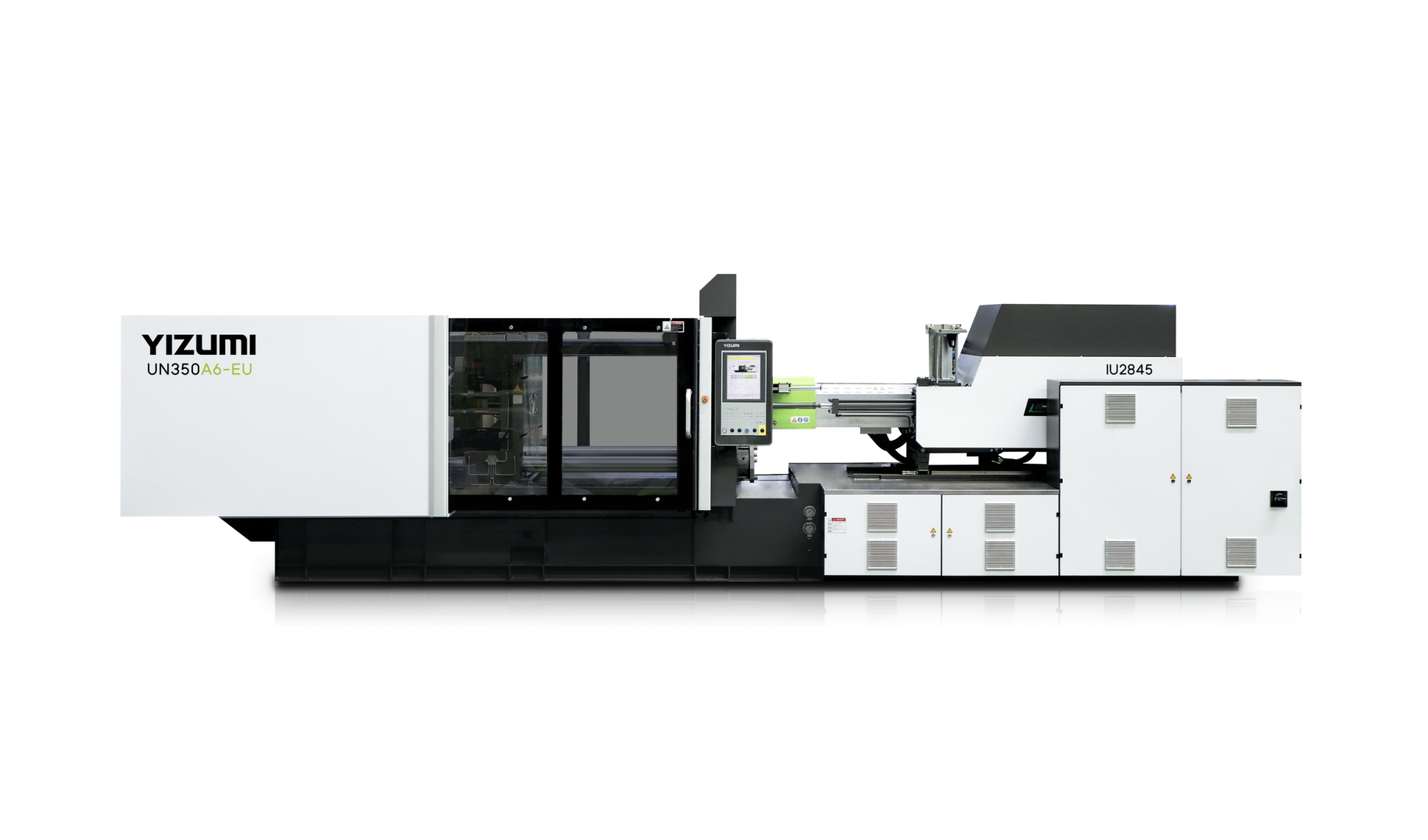

The A6-EU series is an evolution of our most popular model, the A5-EU. This servo hydraulic toggle lock moulding machine strikes an excellent balance of value and efficiency. With updated technology to support energy efficiency and productivity, the new model enhances Yizumi’s competitiveness in the marketplace. The predecessor of the A6-EU had market leading tie bar spacing for each clamp unit, which has been developed even further. Other notable additions to the standard specification include;

These enhancements are in addition to the already high standard specification that came with the A5-EU series.

Using our many years of experience with refurbishing machinery, we’ve tailored UK and EIRE destined Yizumi machines to a unique specification. Come and see for yourself at our working workshop – it’s more than a fancy showroom and you can meet the team.

Packed with features that some manufacturers put on their ‘options’ list.

STV Machinery have worked with Yizumi to customise UK and Ireland bound A6-EU machines for domestic customers, each machine has a high specification to include;